Monday - Friday

08.30 - 12.00 hours

13.00 - 17.30 hours

Saturday 10-13 hours

|

Shopping Cart

Contains:

0 items

|

We are official Pipercross dealer for the Swiss market

Pipercross - Air filter for car, motorbike and motorsport

Â

Pipercross has been developing high performance sports air filters for over 25 years, not only for motorsport but also for the domestic market and distributes the air filters manufactured in England worldwide. Based in Northampton, England, Pipercross is located in one of the most established countries for racing. The most famous competition engines come from English development and production.

Throughout the 25 years of racing experience, the Performance Air Filters have helped many race teams to victories in British, European and World Championships. Working closely with the individual drivers, mechanics and engineers of the teams has greatly enhanced the development of Pipercross air filters.

Today, this allows Pipercross to offer a wide range of specialist, high technology air filter systems tailored to exact requirements.

The flexibility of the production of Pipercross air filters allows to cover almost every application. Whether the filter has to withstand extreme contamination, temperatures or air flows. Likewise, almost any filter can be custom made quickly and cost effectively! From WRC to 2CV competition cars, Pipercross can develop suitable sports air filters that meet the specific requirements and specifications.

Advantages of design, filtering and in-house production

Â

Advantages of the design

Advantages of the design

![]() Fits Plug & Play

Fits Plug & Play

![]() 30 % more Airflow

30 % more Airflow

![]() Can be used as spare part

Can be used as spare part

![]() No negative effect on warranty

No negative effect on warranty

Â

Advantages of filtering

Advantages of filtering

![]() Reduced fuel consumption

Reduced fuel consumption

![]() Improved power and torque

Improved power and torque

![]() First class dirt filtration

First class dirt filtration

![]() Designed to filter better and longer

Designed to filter better and longer

Â

Advantages of in-house production

Advantages of in-house production

![]() 1st hand customer service

1st hand customer service

![]() Washable & reusable

Washable & reusable

![]() Multi-Layer Technology

Multi-Layer Technology

![]() Developed & manufactured in England

Developed & manufactured in England

Â

Oil-free replacement filters

For drivers who need 30% to 40% more airflow* and an oil-free, washable filter without extremely increased intake noise, the replacement filters from Pipercross are the perfect replacement element.

Why are Pipercross air filters oil-free and can a filter without oil work at all?

Almost all well-known manufacturers of replacement filters use cotton gauze as a medium. This medium would indeed have a limited filtering effect without oil.

Pipercross has always taken a different approach and therefore works with a multi-layer polyurethane composite specially developed for Pipercross. Only this material and a processing that is based on almost 30 years of development experience makes it possible to produce oil-free replacement filters at the highest quality level that ensure both maximum torque and optimum engine protection.

Why we do this is obvious:

Oil vapours can literally burn onto the hot film element over time. This can lead to incorrect readings or, worse, failure of the LFM. With Pipercross air filters, you avoid damage and expensive repairs of this kind right from the start.

Performance-optimised and performance-enhanced vehicles can be tuned even more optimally with an oil-free air filter. That is why more and more companies in this industry exclusively use Pipercross air filters. Cleaning an oiled filter (which is usually also folded) is very tedious and time-consuming. A Pipercross filter does not have any oil-covered residues and after quick and easy cleaning it shows 100% of its original performance again. Without the hassle of re-oiling! And last but not least, buying an oil-free Pipercross air filter means that you don't have to buy expensive oils only to pollute the environment with poorly degradable oils during cleaning.

Â

Every original paper filter is oil-free!

And for good reason. However, since a paper filter has a very short service life and also only a limited air flow, an oil-free replacement filter from Pipercross is the perfect alternative. Without compromising on engine protection, performance and with unlimited lifetime.

The technology behind Pipercross air filters

Developed as an original spare part, a Pipercross Panel Filter replaces the factory fitted air filter element. Installation is simple: just replace the old filter with the Pipercross Panel Filter and the engine can breathe freely.

If suspended particles in the air are caught in paper or cotton filters, there is a steadily increasing pressure drop over time, which cuts off the air to the engine and leads to considerable performance losses. Thanks to the deep foam structure of Pipercross air filters, the air flow can pass the trapped dirt particles unhindered.

The technology behind Pipercross air filters

As Pipercross, we offer specially developed air filter designs and manufacturing for all motorsport applications. From foam filtration to carbon fibre composite constructed support frames, Pipercross filters provide the optimum performance and engine protection. We work closely with leading teams and manufacturers in motorsport to produce air filters that meet the exact requirements of the teams and engine manufacturers.

Using our CAD technology, our engineering department can tailor their designs to the exact intake you are developing, determine recommendations for the optimum foam specification and also work out the largest possible surface area for an air filter. In addition, we can test the airflow of filter media. We use our in-house SAE J726c facilities for this purpose.

Â

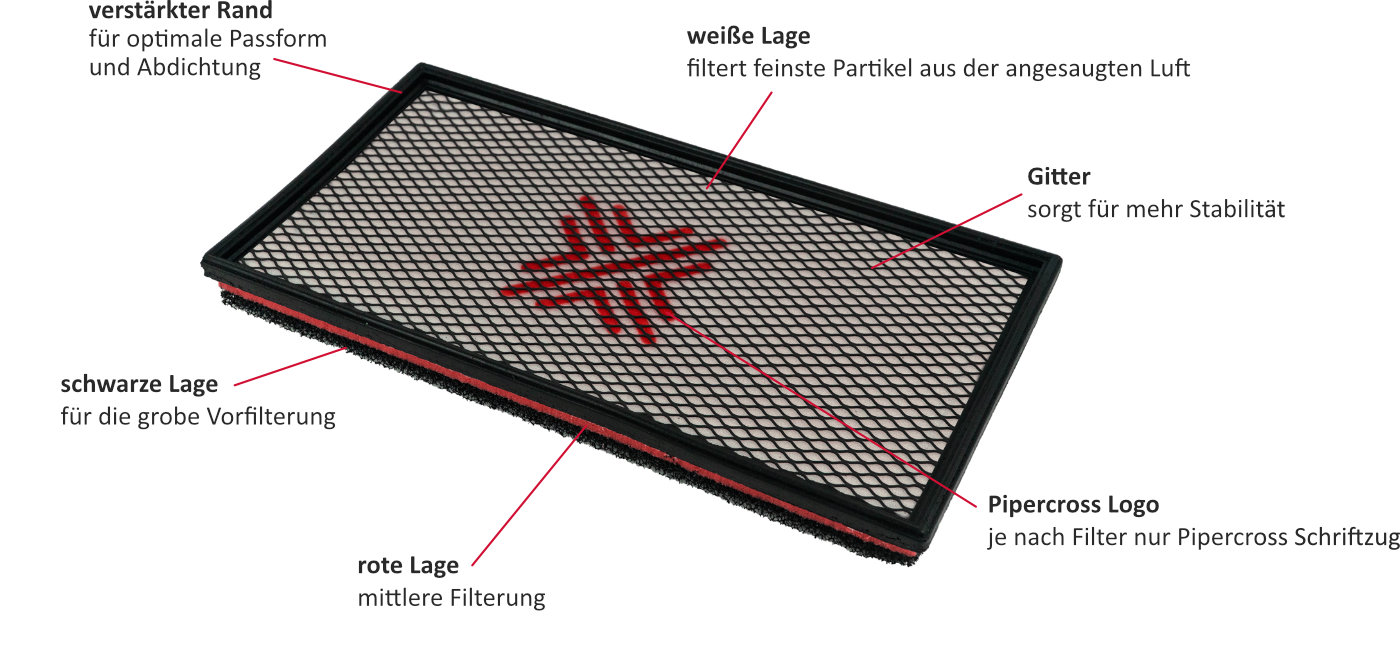

3-stage filter system for car replacement filters

- Layer 1 (black): This layer serves as a pre-filter and retains the coarse-grained dirt such as gravel, leaves, grass and rubber abrasion.

- Layer 2 (red): This would be the finest layer in most automotive filters. This is where mud, dust and sand are trapped

- Layer 3 (white): This is the most finely porous layer in the system. It serves as a safety barrier. Due to the harsh operating conditions and high requirements for these filters, it is essential that even the finest particles are reliably filtered out. A side effect of this layer is that water droplets are very finely atomised, so that only a fine spray may enter the engine and not thick drops. ***This type of filter medium can absorb more than four times its own weight in foreign particles before it shows any signs of clogging!

Â

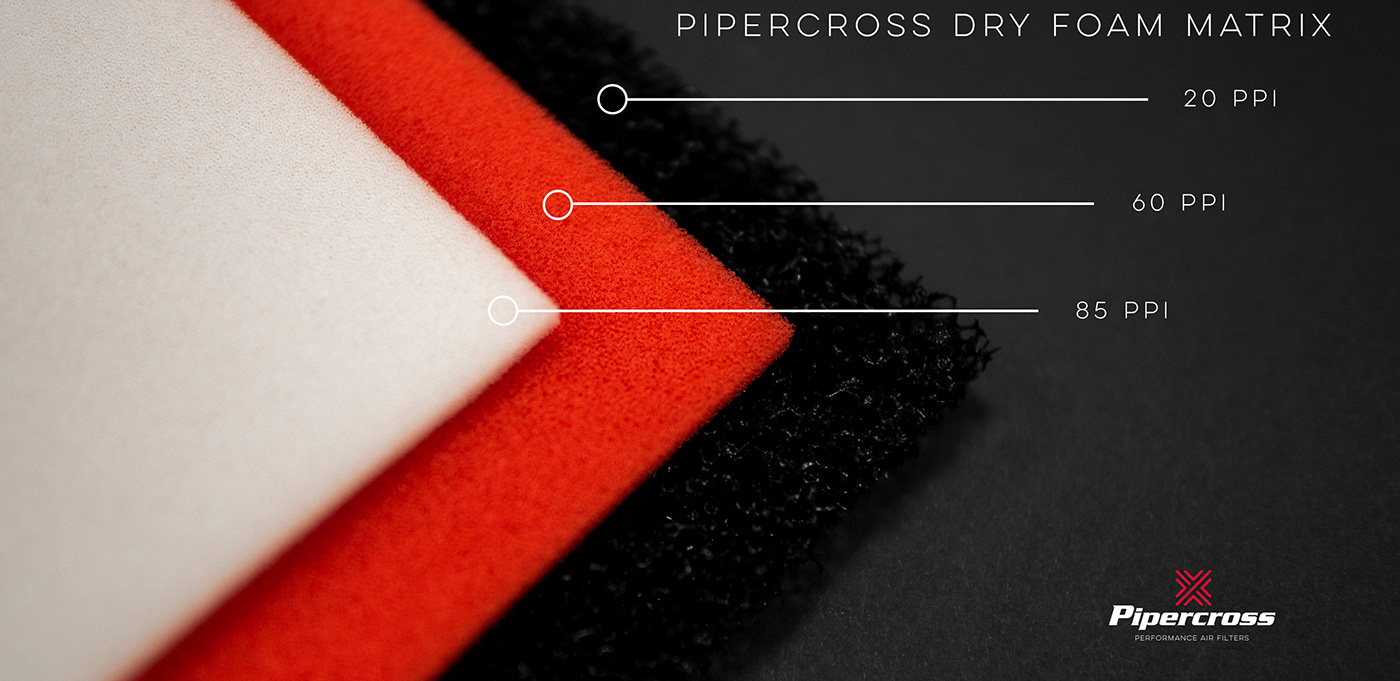

The material explained in more detail

At the heart of the Pipercross air filter is a specially developed polyurethane foam, which serves as the filter medium and offers both better performance and a longer service life than paper.

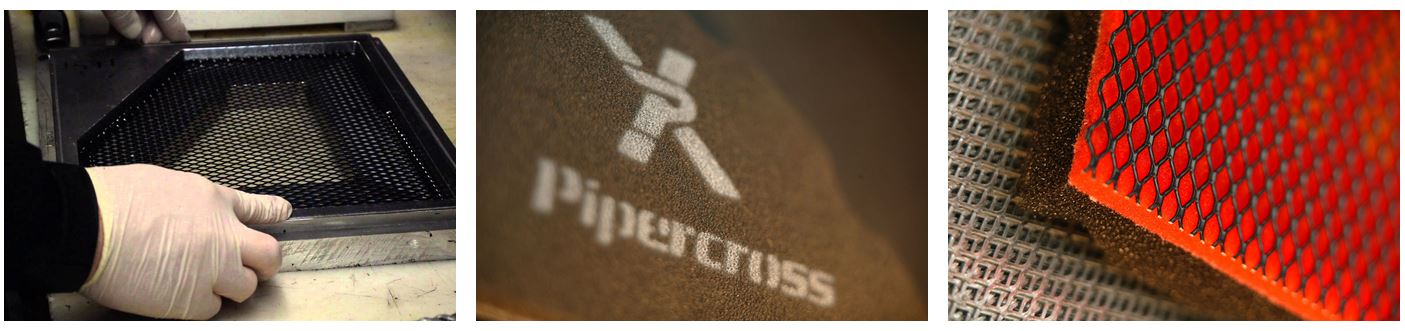

Pipercross Mesh Structure

The mesh structure of the Pipercross foam is based on a sophisticated process. The Pipercross foam is first produced in a chemical reaction and then placed in a gas-filled combustion chamber where a controlled explosion burns off the cell walls to create a skeletal cell structure under strict quality control. This process ensures that the foamed special material consists of tiny open cells that absorb impurities from the air.

We measure the cell size of the foam, i.e. its porosity, in PPI (pores per inch). Pipercross air filters use up to six layers of foam where the pores get smaller and smaller in the direction of the air flow.

Some of the foam layers are hot-laminated, with a nylon mesh inserted as an intermediate layer, so that a stable, fail-safe transition is created without affecting the airflow through the material, as would be the case with conventional bonding methods.

Â

Â

Cross-section through the three-layer foam

Pipercross filters owe their long service life or long maintenance and cleaning intervals to the dirt-holding capacity of the foam cells, because the air flow is only blocked when all cells in a foam layer are really completely filled. Our filters are designed to trap dirt particles already in the outer layers, so that the inner layers serve as a filter reserve to ensure maximum engine protection.

Different surface treatments lead to optimal results for very specific different external conditions. Two examples of these different surface treatments at Pipercross are a dry layer of coarse material or a profiled layer to increase the surface area.

Please use only approved Pipercross oils according to the instructions for our multi-layer foam filters. The "dry" Pipercross foam must not be oiled!

- Clean the air filter after approx. 15,000 to 20,000 kilometres or 1x per year.

- The best time to clean the air filter is at the end of May/June.

- Motorbike air filters must be re-oiled after cleaning.

- We recommend our Pipercross cleaner for dry air filters, or the set with cleaner and oil for oiled air filters.

How to clean oil-free Pipercross Air Filters